Spark Erosion

In addition to removing glow plugs and injectors, Vibropac also specializes in the removal of broken taps, drills and other extremely hard material which cannot be removed with ordinary tools.

For example, a bolt may break during work on an engine block and it is impossible to remove it with conventional tools without damaging the hole, thread or engine block itself. The bolt can no longer be mechanically machined because it is simply too hard.

There is only one solution to save a lot of damage, but also extra costs and time: Spark Erosion

What is spark erosion?

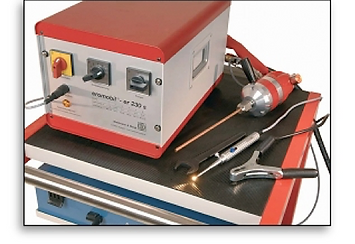

Spark erosion is a technique where an electrode of copper is sunk into the material. This material can be that of a tap, drill or any other object that is stuck. Between the material and the electrode, a flame arc is created causing the material to be machined. With sufficient knowledge and craftsmanship, the material can be completely machined without damage to the hole or thread where the tap, drill or any other hard object is located.

Spark Erosion requires a special approach

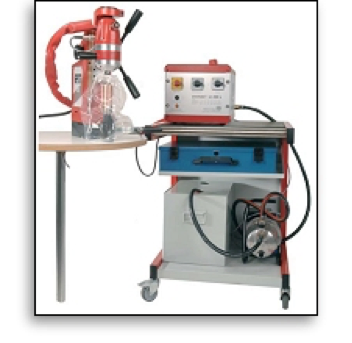

Spark erosion is a very precise job and can only be successful using craftsmanship and the right tools. In this case we are working with a spark erosion machine that can only be operated by our technicians at Vibropac so any repair need to take place in our workshop.

Specifications:

- M2 till ± M40

- Power: 57600 Watt

- Diameter: from 1 mm till 17 mm

- Maximum depth: 300mm (because of accuracy*)

*Electrode is vibrating during operation so to guarantee a very precise repair, we do not use electrodes longer than 300mm

Casus

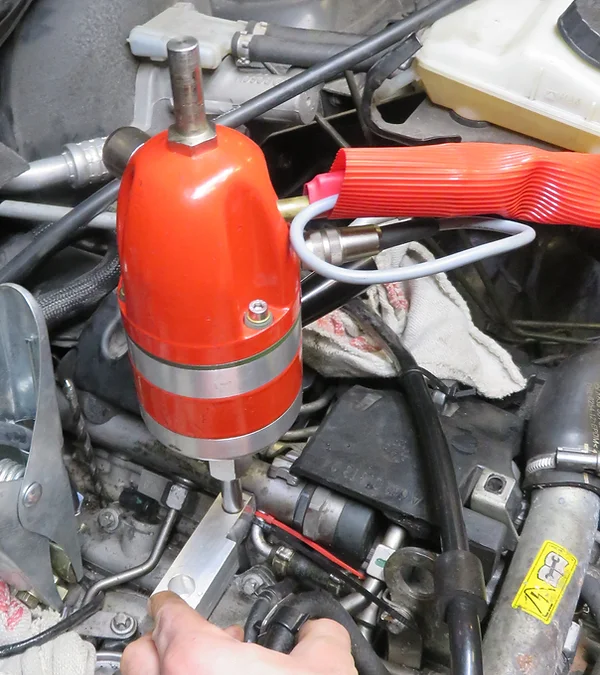

This case is about a Mercedes Vito V6 CDI motor where a broken tap remained in the hole of where the glow plug normally goes. This tap cannot be machined with a drill or cutter, because the material is too tough. The only solution to remove the broken tap is to use spark erosion.

The broken left turning tap is clearly visible in the hole where normally the glow plug goes in the engine block. Now would be a good time to contact us and make use of our eroding service at location. We will make an appointment to where and when the car can come to our location. We will ensure that everything comes out neatly.

The first step is to measure some dimension and make a mold. This mold will be designed to perfectly fit on this specific engine and in this position on the engine block.

The spark erosion machine is placed on the tap. A special guide that was made during the previous step is in line with the hole. This is done so that the electrode can slide in and make optimal contact with the broken tap. As a result, the spark erosion machine is able to erode it completely.

In this case, a guide has been made for the hole where the tap is located. The guide allows the electrode to make optimal contact with the stuck tap.

Success! The remnants of the tap have been eroded. What remains is an empty clean hole ready again to install a glow plug. Note that the spark erosion machine itself does not damage the hole or the screw thread. However, you can see that the hole is no longer round. This was due to the fact that the broken tap had been hit with great force, most likely a hammer.

If this happens to you, immediately stop trying and give us a call! We strongly recommend this to avoid unnecessary damage to the engine. In addition, it saves considerably in time and costs that you spend solving this problem.

In this case, the diameter of the hole is first increased to make it round again*

Then an adapter reducing the diameter is cut to size and placed in the hole with the correct internal thread size. The hole is now the correct diameter again and a new glow plug can be installed.

* in most cases this is step unnecessary, because the hole is still round.

Do you have a problem?

Suffering from a broken bolt or tap? Then STOP trying to take it out immediately and call Vibropac! We can help you quickly!

In this way unnecessary damage to the engine is prevented and it also saves you considerable time and costs that you have lost with ‘solving’ this problem, which actually only makes the problem worse.

Go to serviceform